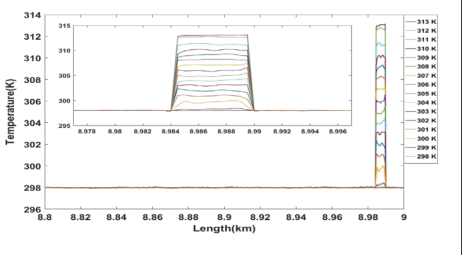

Distributed Temperature Sensing Systems (DTS)

Raman-based DTS system exploits the spontaneous Raman scattering resulting from the interaction between light (photons) and molecular vibration modes (optical photons). It gains insight into your process by using an optical fiber as a sensing element. The DTS TATUS is a compact and industrial-grade static detector designed for very highly reliable, stable and long-term operation. It is integrated by fiber optics, optoelectronics, and high-speed signal acquisition. The embedded software and hardware make it very stable, compact, and low power consumption. The TATUS has been widely used in electric power, transportation, petrochemical, coal, metallurgy, and other industries.

What we have

Key Features

- High Integration

- Small Space Resolution

- Stable And Reliable

- Very Low Power Consumption

- High Dynamic Range

Few Application

- Power Cable Monitoring

- Panel Temperature Monitoring

- Surface Temperature Monitoring

- Conveyor Fire Detection

- Tunnel Monitoring

SPECIFICATION

| PARAMETER | UNIT | VALUE |

|---|---|---|

| Distance Range | Km | 5 OR 10 |

| Number Of Channels | Number Of Channels | 4 |

| Consumption | W | <50 |

| Response Time | s | <50 |

| Operating Wavelength | nm | 1550 |

| Positioning Resolution | m | 1 |

| Temperature Resolution | - | 0.2 |

| Temperature Resolution | - | 01 |

| Optical Fiber | MM | Optical Fiber |

| Optical interface | - | E2000 / APC |

| Communication | - | RS232 / RS485 / RJ45 / ETHERNET |

| Dimension | - | 2U |

| Weight | KG | 2 |

| Input | - | 24VDC / 220VAC |

| Humidity | - | 95% without condensing |

| Operating Temperature | °C | 0 to 40 |

| Interface | Interface 1RJ45 Ethernet 10/100/1000baseT port | |

| Communication Protocol | MODBUS, TCP/ip |