Magnetic Level Gauge Overview

The HAWK Magnetic Level Gauge (MLG) is widely applied in the

monitoring and process control

of liquid level and interface for many industries; such as petroleum, chemical,

power, paper,

metallurgy, water treatment etc.

The SPI and TBI are the standard and special magnetic level gauges of HAWK. The

products

are suitable for real time, precise, safe and reliable continuous measurement of

process level.

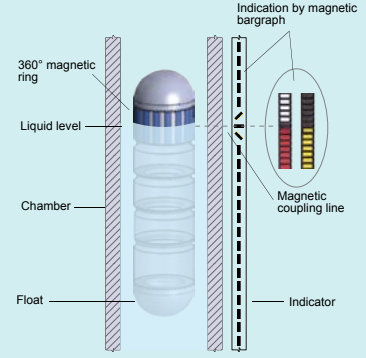

The design adopts a 360° magnetic ring which is hermetically sealed and

incompressible.

The indicator uses hermetical sealed glass tube technology to clearly indicate the

level, which

eliminates the common problems of glass gauges, such as vapour, condensation and

liquid

leakage etc.

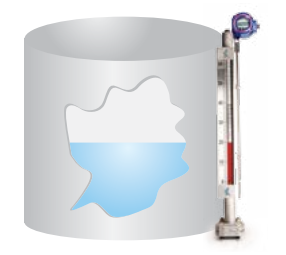

Principle of Magnetic Level Gauge

Based on the principle of

magnetic coupling and

buoyancy, the magnetic level gauge provides real-time

measurement for level and interface.

HAWK’s Magnetic Level Gauge (MLG) is connected to a

process vessel. Within the chamber is a float containing a

360° magnetic ring. Outside of the chamber is an indicator

equipped with a vacuum glass tube, which contains a

bicoloured two-face magnetic bargraph. In response to

the level movement, the float moves accordingly, forcing

the magnetic bargraph to turn and change color. True

liquid level is indicated or “read” from the corresponding

point on the measuring scale.

Applications of Magnetic Level Gauge

- Boiler: Steam drum liquid level

- Power generation: Auxiliary machinery liquid level (HP reheater, LP reheater, deaerator, condenser and heating network heater etc), chemical water

- Coal Chemical: Methanol, dimethyl ether, synthesis ammonia/urea, MTO, CTL, SNG

- Silicon industry: Organic silicon, polycrystalline silicon

- Petroleum and petrochemical: Oil and gas, ethylene, trimerization and etc.

- Fine Chemicals: Methane oxide, epoxy ethane, aniline, PTMEG, BDO, carbon fiber, POM,acetic acid, styrene, rubber, crude benzol refining

- Others: Metallurgy, paper-making, water treatment, biological, pharmaceutical, food and beverage etc.

Product Application of Magnetic Level Gauge

Application I:

High Temperature and High Pressure (HTHP) Application

- Designed for HTHP, all components are incompressible

- Maximum process temperature: 1000°F or 538°C

- Maximum process pressure: 6000 psig or 42MPa

- Suitable for boiler steam drums, power plant auxiliary machinery, hydrogenation and other HTHP working conditions

Application II:

Low temperature / Ultra-low temperature application

- Designed for low temperature and frost prevention, all components hard and anti-compression

- Minimum process temperature: -320°F (-196°C)

- Absolutely avoids condensation, frost, freezing and etc.

- Suitable for ethylene, Rectisol and other low temperature/ ultra-low temperature working conditions

Application III:

Special Materials

- 304SS+PTEF, Hastelloy C-276, Zr 702, Ni-6 and etc.

- Wide range of temperature, pressure and corrosion resistance

- Acetic acid, acetic anhydride, chlor-alkali suitable for chemical industry and other corrosive working conditions

Application IV:

Integrated Application

- Integrated application with level transmitters/switches

- Local indication and remote signal simultaneously

- Measure multiple process interfaces

- Reduced costs of product and maintenance